|

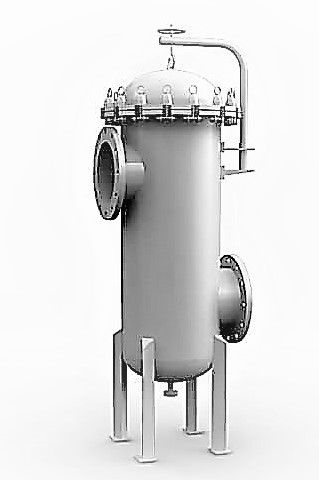

Simplex Basket Strainers

Simplex Basket Strainers Specification

- Inlet Diameter

- 2 inch to 24 inch

- Shape

- Cylindrical

- Outlet Diameter

- 2 inch to 24 inch

- Sealing

- Gasket (Neoprene/EPDM/Nitrile)

- Pore Size

- 10-1500 micron

- Filter Rating

- 10 to 1500 micron

- Pressure

- Up to 16 bar

- Filter Media

- Perforated Sheet or Wire Mesh

- Product Type

- Industrial Strainer

- Material

- Stainless Steel, Mild Steel, Cast Iron

- Type

- Simplex Basket Strainer

- Cartridge Style

- Basket Type

- Diameter

- 2 inch to 24 inch (Custom sizes available)

- Efficiency

- Up to 98%

- Application

- Liquid Filtration, Water Treatment, Chemical Processing, Oil & Gas, Power Plants

Simplex Basket Strainers Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Year

- Delivery Time

- 1 Months

- Packaging Details

- as per standard

- Main Domestic Market

- All India

About Simplex Basket Strainers

Being a renowned firm, we are offering broadrange of Simplex Basket Strainers. It is engineered with a rigidconstruction and modern techniques. We Design high quality Products with widerange of flow capacities up to 2000 M3/Hr.

Strainers are proposed for applications, whereverlarge amounts of solid contaminant particles are expected. Strainers are permittedto filter wide range of fluids and retain any size of solid contaminantparticles. Basket element is manufactured from different type of wage wire or wiremesh with supported by perforated sheet to get proper strength to basketelement for increasing contaminates holding capacities.

Operation: -

This Product isideally used to separateSolid contaminants Particles from liquid or gas. Contaminated fluid or gas is enteredand distributed equally around the Basket Element and passed through BasketElement from outside to inside or inside to outside depended on customerrequirements. And filtered liquid or gas exit from outlet connection. Solidelements are collected and removed easily from strainers. It is easy tomaintain and clean in a reliable manner without making any extra efforts.

Features:

Technical Data:

Design capability: -

Basket Element: -

Material of Construction (Strainerbody): -

Gasket Material: -

End Pipe Connections: -

Applications:

Processindustries & any mor

Versatile Flow and Connection Options

Simplex Basket Strainers can be installed using flanged, screwed, or butt weld end connections, accommodating various piping systems in industrial settings. Their standard flow direction ('in to out') maximizes particulate capture, and each unit comes with a drain plug for convenient maintenance. These strainers are ideal for multiple applications due to their compatibility and flexible installation options.

Superior Filtration and Customization

Featuring a basket-type cartridge available in perforated or mesh-lined designs, these strainers achieve fine filtration between 10 to 1500 microns. Basket materials such as SS304, SS316, brass, and Monel are supplied as per customer requirements, ensuring chemical compatibility and longevity even in aggressive environments. Custom sizes and designs are available to meet unique project specifications.

User-Friendly Maintenance

Maintenance is streamlined with a removable top cover, allowing operators easy access for basket cleaning or replacement. The inclusion of a drain plug further simplifies scheduled maintenance or emergency cleaning, minimizing downtime. The robust epoxy coating on MS/CI grades enhances durability, ensuring reliable performance even in demanding conditions.

FAQ's of Simplex Basket Strainers:

Q: How is a Simplex Basket Strainer installed in a pipeline?

A: Installation is straightforward as Simplex Basket Strainers are designed for inline placement using flanged, screwed, or butt weld end connections. Position the strainer upright, match the inlet and outlet to the pipeline, and securely connect using appropriate gaskets and fasteners. Ensure proper alignment to facilitate standard 'in to out' flow direction for optimal filtration.Q: What type of applications are these strainers suitable for?

A: These strainers are ideal for liquid filtration in water treatment plants, chemical processing, oil and gas installations, and power plants. Their robust construction and customizable features make them suitable for a wide range of industrial and process applications requiring efficient removal of particulates from fluids.Q: When should the basket be cleaned or replaced?

A: The strainer basket should be cleaned whenever there is a noticeable drop in system pressure or routine maintenance is scheduled. The top cover design allows for quick removal and inspection; heavily clogged baskets may require cleaning or replacement, depending on wear and application demands.Q: Where can custom sizes or material options be requested?

A: Custom sizes (ranging from 2 to 24 inches or beyond) and alternative basket materials such as SS304, SS316, brass, and Monel can be specified at the time of order with the manufacturer or supplier in India. This ensures the strainer meets precise application requirements and compatibility needs.Q: What is the process for removing contaminants from liquid using this strainer?

A: Contaminated liquid enters the strainer, flows through the perforated or mesh-lined basket (in to out), and solid particles are retained within the basket. Cleaned liquid exits the outlet, while the basket can be periodically removed for cleaning, keeping the system free from blockages.Q: How does the strainer benefit industrial operations?

A: With up to 98% filtration efficiency and a filter rating from 10 to 1500 microns, the strainer protects downstream equipment from damage and reduces maintenance frequency. Its easy-access design and durable construction ensure long-term reliability and cost-effective operation in critical process environments.

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Year

- Delivery Time

- 1 Months

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in BASKET STRAINERS Category

Cross Design Type Basket Strainers

Minimum Order Quantity : 1 Piece

Filter Rating : 10 to 2000 microns

Diameter : Available from 2 inch up to 24 inch

Efficiency : High filtration efficiency up to 95%

Pressure : Max 16 bar

Product Type : Basket Strainer

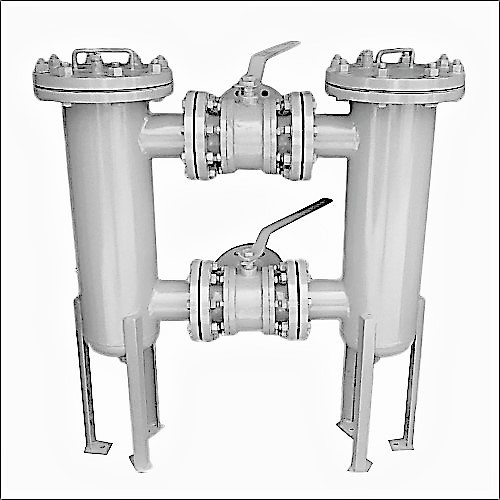

Duplex Basket Strainers

Minimum Order Quantity : 1 Piece

Filter Rating : 10400 micron

Diameter : 200 mm

Efficiency : 99%

Pressure : Up to 10 Bar

Product Type : Basket Strainer

|

MISHU ENGINEERING CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |