|

Duplex Basket Strainers

Duplex Basket Strainers Specification

- Filter Media

- Perforated/mesh stainless steel

- Pressure

- Up to 10 Bar

- Sealing

- Gasket sealing

- Inlet Diameter

- 100 mm

- Outlet Diameter

- 100 mm

- Filter Rating

- 10-400 micron

- Pore Size

- 10 micron

- Shape

- Cylindrical

- Product Type

- Basket Strainer

- Material

- Stainless Steel

- Type

- Duplex Strainer

- Cartridge Style

- Basket type

- Diameter

- 200 mm

- Efficiency

- 99%

- Application

- Industrial fluid filtration, Water treatment, Chemical processing

- Operating Temperature

- Up to 120°C

- Corrosion Resistance

- Excellent

- End Connection

- Flanged

- Surface Finish

- Polished

- Color

- Metallic Silver

- Installation Position

- Horizontal/Vertical

- Flow Capacity

- Up to 400 m³/hr

- Switch Mechanism

- 3-way valve for duplex operation

- Maintenance

- Easy basket removal

Duplex Basket Strainers Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Year

- Delivery Time

- 1 Months

- Packaging Details

- as per standard

- Main Domestic Market

- All India

About Duplex Basket Strainers

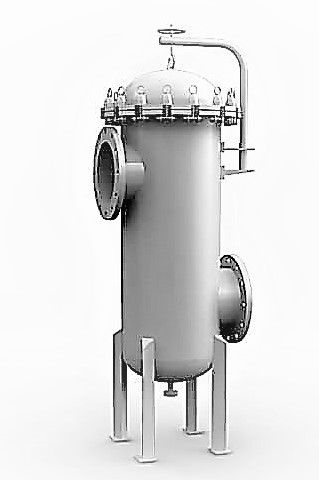

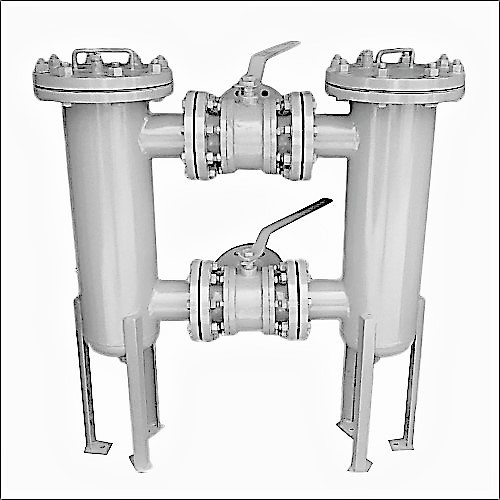

Duplex Basket Strainers

We have established ourselves in presenting a wide range of Duplex Basket Strainers. This product is designed for continuous process line, where one housing is under operation and another one is stand by, which can be changed by 3-Way ball valves or Butterfly valves without interruption of process. this product is easy for maintenance without stoppage of flow. We Design high quality Products with wide range of flow capacities up to 2000 M³/Hr.

Strainers are proposed for applications, wherever large amounts of solid contaminant particles are expected. Strainers are permitted to filter wide range of fluids and retain any size of solid contaminant particles.Basket element is manufactured from different type of wage wire or wire mesh with supported by perforated sheet to get proper strength to basket element for increasing contaminates holding capacities.

Operation: -

This Product is ideally used to separate Solid contaminants Particles from liquid or gas. Contaminated fluid or gas is entered and distributed equally around the Basket Element and passed through Basket Element from outside to inside or inside to outside depended on customer requirements. And filtered liquid or gas exit from outlet connection. Solid elements are collected and removed easily from strainers. It is easy to maintain and clean in a reliable manner without making any extra efforts.

Features:

· Easy dismantle for cleaning and maintenance.

· Eye Bolt type cover locking structure

· Less pressure drop design because of considering of higher filtration area.

· Flow can be converted from one housing to others by 3-Way ball valves, 2-Way ball valves & butterfly valves as customer requirement.

· Suitable for high temperature and pressure.

· Suitable for large amount of solid contaminant particles

· High dirt holding capacity.

· Hinge or Davit pipe assembly available for quick opening of cover flange.

· Strainers are made with Mirror, electro polishing to resist dirt and scale.

· One coat of epoxy paint applied on outside surface for CS / MS Constructed.

· Pressure gauge arrangement at top to monitor internal pressure of Strainers.

· Safety valve at inlet/out connection to reduce internal pressure if increase.

· Arrangement of difference pressure monitoring instruments.

Technical Data:

Design capability: -

· Customized Design available.

· Designed Free flow area of basket 4-6 times higher then pipe cross section area.

· Flow rate up to 1500 M³/hr.

· Mechanical Strength (ASME) Design Calculation on customer Request.

· Designed suitable Flow direction in to out or out to in as per customer requirements.

· Multi basket elements in single strainer design available for easy cleaning and maintenance for high flow rate strainers.

· End connection up to ½ inch NPS to 24 inches NPS in Pipe schedule.

Basket Element: -

· Filter Media- Wire Mesh + Perforated sheet, Perforated Sheet, Wage-Wire

· Filtration ratingup to 500 Mesh (up to 20 Micron)

· Material of construction SS 304, SS 304L, SS316, SS316L

· Diameter of basket strainer min. 100 mm to max. customized.

Material of Construction(Strainer body): -

· SS 304

· SS 304L

· SS 316

· SS 316L

· Duplex Steel (SS 2205)

· Carbon Steel (SA 516 Gr 70)

· Mild Steel (IS 2062)

· CS/MS + Rubber lining.

· CS/MS + FRP Lining.

Gasket Material: -

· Neoprene

· Natural Rubber

· Silicon

· Buna-N

· PTFE

· EPDM

· CAF

· Spiral Wound Gasket

End Pipe Connections: -

· ANSI B16.5 Flanged.

· BS-10, Table D, E, F Flanged.

· Butt-Welded Pipe schedule.

· Tri Clover Adaptor

· Threaded

· Socket-welded

Applications:

· Water Treatment

· Chemical

· Oil & Gas

· Power-plant

· Textile

· Cement Plant

· Fertilizers

· Refineries

· Petrochemical

· Process industries & any more

Superior Corrosion Resistance

Engineered from premium stainless steel, these duplex basket strainers deliver outstanding resistance to corrosive fluids, ensuring long-term reliability in demanding environments such as chemical processing and water treatment.

High Flow Efficiency and Flexibility

With a maximum flow rate of up to 400 m3/hr and a versatile 3-way valve design, the strainer supports continuous operation and minimal downtime, handling both horizontal and vertical installations based on your setup needs.

Simplified Maintenance and Operation

Routine upkeep is made easy with accessible basket removal, reducing process downtime. The gasket-sealed, basket-type cartridge ensures quick service intervals and reliable leak-proof operation during industrial filtration tasks.

FAQ's of Duplex Basket Strainers:

Q: How is the Duplex Basket Strainer installed?

A: The strainer is designed for flexible installation and can be mounted in either horizontal or vertical pipe configurations, using flanged end connections for secure integration into your industrial system.Q: What types of fluids can this strainer handle?

A: This duplex basket strainer is suitable for a variety of industrial fluids, including water, chemicals, and other process liquids, thanks to its stainless steel construction and excellent corrosion resistance.Q: When should the basket filter be cleaned or replaced?

A: Basket cleaning or replacement should be performed based on filtration load and pressure drop across the strainer. Easy basket removal design allows for swift maintenance during scheduled plant shutdowns or when differential pressure increases.Q: Where is this strainer commonly used?

A: It finds application in industrial fluid filtration processes, water treatment facilities, and chemical manufacturing plants where high filtration efficiency and durability are required.Q: What is the filtration process within the strainer?

A: Fluid enters through the 100 mm inlet, passing through a perforated or mesh stainless steel basket that removes particles as small as 10 microns, then exits through the 100 mm outlet, delivering clean, filtered media.Q: How does the duplex feature benefit operation?

A: The duplex configuration, featuring a 3-way valve, allows for seamless switching between baskets during cleaning, so filtration can continue without interrupting the process flow.Q: What are the main benefits of using this product?

A: Key advantages include 99% filtration efficiency, robust corrosion resistance, quick maintenance, high flow capacity, reliability under high pressure (up to 10 Bar), and adaptability to various installation setups.

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Year

- Delivery Time

- 1 Months

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in BASKET STRAINERS Category

Cross Design Type Basket Strainers

Minimum Order Quantity : 1 Piece

Sealing : Bolted cover with gasket seal

Product Type : Basket Strainer

Application : Industrial fluid processing, Water treatment, Chemical, Petrochemical, Power plants

Inlet Diameter : Customized, typically matches pipeline diameter

Type : Other, Cross Design

Simplex Basket Strainers

Minimum Order Quantity : 1 Piece

Sealing : Gasket (Neoprene/EPDM/Nitrile)

Product Type : Industrial Strainer

Application : Liquid Filtration, Water Treatment, Chemical Processing, Oil & Gas, Power Plants

Inlet Diameter : 2 inch to 24 inch

Type : Other, Simplex Basket Strainer

|

MISHU ENGINEERING CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |